◆ Application scope

metallurgy:Continuous casting water, high-pressure dephosphorization water, clean circulating water, turbid circulating water filtration, full filtration of cooling water, side filtration, nozzle protection

power:Turbine cooling water filtration, ash water recovery filtration, dust suppression nozzle protection, full filtration and side filtration of cooling tower water

raw water:Filtering of sand, algae, and organic matter during extraction of lake, river, reservoir, well, rainwater, and groundwater

agriculture:Sprinkler and drip irrigation water treatment

other:Construction, steel, petroleum, chemical, electronics, power generation, textile, paper, food, sugar, pharmaceutical, plastic, automotive industries

Widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment and other fields. Domestic application water pretreatment, various industrial water production, water supply treatment pretreatment, reclaimed water treatment, wastewater treatment, various operating conditions circulating water filtration

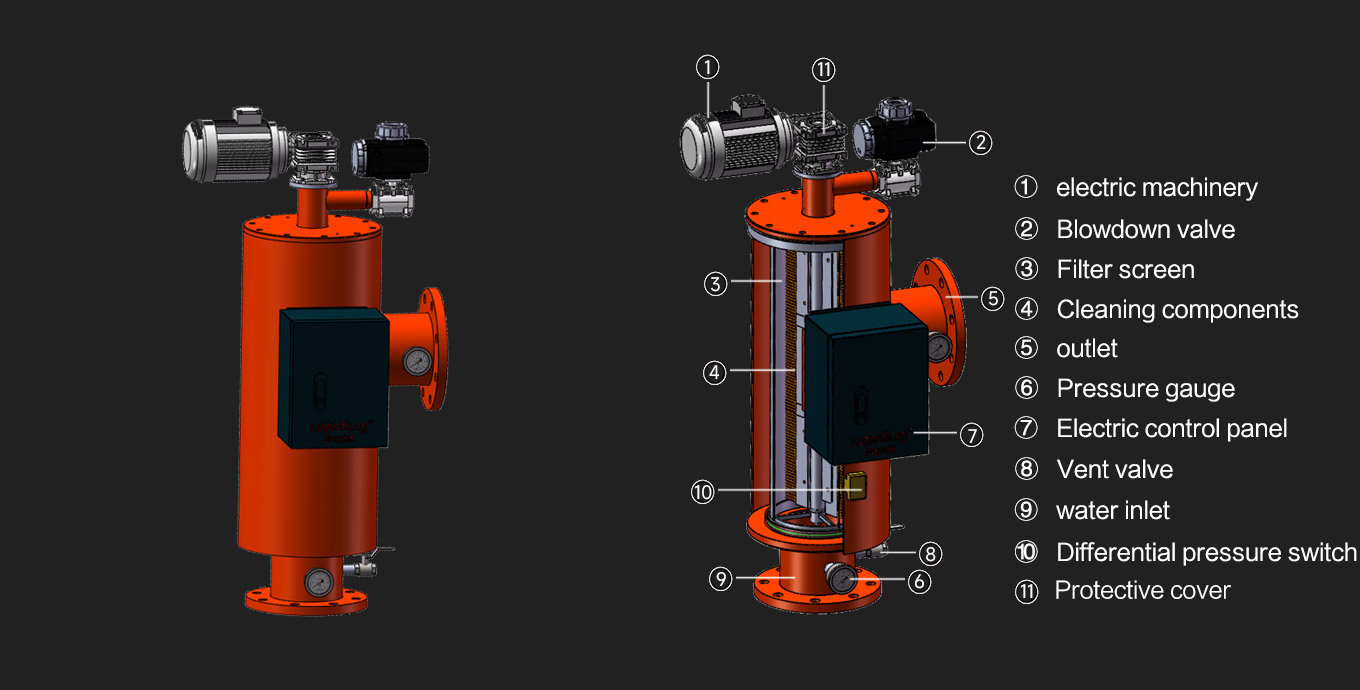

◆introduce

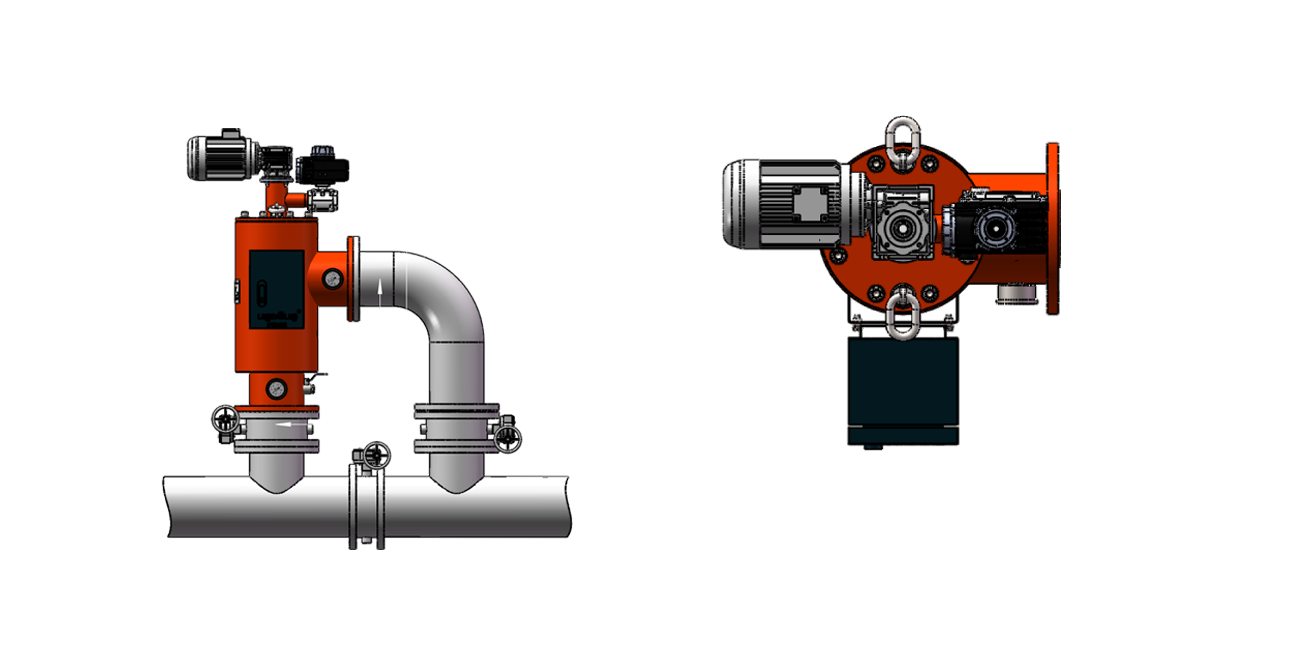

The fully automatic self-cleaning filter is a precision equipment that directly intercepts impurities in water through a filter screen to purify water quality and protect the normal operation of other equipment in the system. Water enters the self-cleaning filter body from the water inlet. Due to intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition and signal the sewage valve to automatically discharge. The fully automatic self-cleaning filter overcomes the many shortcomings of traditional filtering products, such as low pollution capacity, easy blockage by dirt, the need to disassemble and clean the filtering part, and the inability to monitor the filter status. It has the function of filtering the raw water and automatically cleaning and discharging the filter element. The system also provides uninterrupted water supply during cleaning and discharging, which can monitor the working status of the filter with a high degree of automation. Covering various filtration accuracy requirements from 10um to 3000um, we provide customers with circulating water filtration equipment.

◆ Features of fully automatic self-cleaning filter

◆The design structure is simple.

◆Short backwash time, low flow rate, and pressure loss.

◆The control system is intelligentized (PLC, PAC) and has a high degree of automation.

◆The device can be connected to the central control system.

◆High precision filtration ensures stable effluent quality.

◆The filter is used for life and does not require replacement.

◆Long service life.

◆Suitable for different raw water quality and water usage requirements.

◆Less vulnerable parts, no consumables, low operating costs, and simple operation and management.

◆Automatic backwashing without interruption of flow.

◆Selection of fully automatic self-cleaning filters

◆Filtering accuracy conversion

|

micron |

10 |

25 |

30 |

40 |

50 |

80 |

100 |

120 |

150 |

200 |

400 |

800 |

1500 |

3000 |

|

Mesh count |

1500 |

650 |

550 |

400 |

300 |

200 |

150 |

120 |

100 |

80 |

40 |

20 |

10 |

5 |

|

millimetre |

0.01 |

0.025 |

0.03 |

0.04 |

0.05 |

0.08 |

0.1 |

0.12 |

0.15 |

0.2 |

0.4 |

0.8 |

1.5 |

3.0 |

◆How to choose a suitable filtering scheme

In order to achieve the best filtering effect and meet the user's requirements for water, electricity, and labor saving to the maximum extent, please consult the LuoLun(LUO DAO LUO) filtering dealer. LuoLun(LUO DAO LUO) filtration authorized agents and distributors have received professional technical training from LuoLun(LUO DAO LUO) filtration experts. They will make the best choice for you with their professional knowledge, rich market experience, and rigorous scientific attitude.

◆When selecting filters, please consider the following factors

▲Water treatment capacity

▲Pipeline pressure of the system

▲User requested filtering accuracy

▲Concentration of suspended solids in filtered impurities

▲Physical and chemical properties of filter media

◆Special Purpose Filter

LuoLun(LUO DAO LUO) filtration can be designed and produced for various pressure ranges according to user needs; LuoLun(LUO DAO LUO) filtration uses a special process to produce filters with temperatures up to 95oC. For filters that need to work in cold conditions, LuoLun(LUO DAO LUO) filtration will use a special filtration control system; In response to the strong corrosiveness of seawater, LuoLun(LUO DAO LUO) uses special materials such as nickel and titanium alloy for filtration, and performs special processing on the filter; LuoLun(LUO DAO LUO) filtering can provide targeted solutions based on user specific operating conditions and requirements.